What Is a Risk Assessment?

A risk assessment is a systematic process that identifies, evaluates, and manages potential risks within a specific context. It involves assessing hazards, estimating the likelihood of harm, and implementing control measures to reduce or eliminate risks. Risk assessments are essential for several reasons:

- Legal Compliance:

- Regulatory bodies often require organizations to conduct risk assessments. Compliance with health and safety laws is crucial to avoid penalties and legal consequences.

- Workplace Safety:

- Risk assessments enhance safety by identifying hazards and implementing preventive measures. They protect employees, visitors, and anyone affected by the organization’s activities.

- Decision-Making:

- Organizations use risk assessments to make informed decisions about processes, equipment, and procedures. Assessments guide resource allocation and prioritize risk reduction efforts.

- Continuous Improvement:

- Regular risk assessments promote ongoing improvement. Organizations can adapt to changing circumstances, update controls, and address emerging risks.

- Risk Communication:

- Risk assessments facilitate communication among stakeholders. Clear documentation ensures everyone understands risks and mitigation strategies.

How do I do Risk Assessment?

Completing a thorough risk assessment is crucial for maintaining workplace safety.

Here’s a step-by-step guide, incorporating guidance from the Health and Safety Executive (HSE):

- Identify Hazards:

- Begin by carefully identifying potential hazards within your workplace. Consider anything that could cause harm to employees or visitors. Examples include machinery, chemicals, electrical equipment, or even slippery floors.

When identifying hazards in a workplace for a risk assessment, several common issues can arise. Here are some to consider;

- Hidden Hazards:

- Some hazards may not be immediately obvious. Look beyond the obvious risks and consider less apparent dangers.

- For example, inadequate lighting, poor ergonomics, or psychological stressors might not be readily visible but can impact safety.

- Complacency and Familiarity:

- Employees who work in the same environment daily may become complacent.

- Familiarity can lead to overlooking hazards or assuming that everything is safe.

- Non-Routine Operations:

- Focus not only on routine tasks but also on non-routine activities like maintenance, cleaning, or changes in production cycles.

- These situations can introduce unique hazards.

- Vulnerable Workers:

- Consider workers with specific requirements, such as young workers, pregnant employees, or people with disabilities.

- Their needs may differ, and hazards affecting them should be addressed.

- Lack of Employee Input:

- Involve employees in hazard identification. They often have valuable insights.

- Workers on the ground may notice risks that management overlooks.

Remember, thorough hazard identification is essential for effective risk assessments

2. Assess Risks:

- Thoroughly evaluate the severity of each hazard and the likelihood of it causing harm. Consider who might be affected (employees, contractors, visitors). Use the HSE’s risk assessment template to record your findings.

When calculating a risk rating think of the following:

- Severity Assessment:

- Evaluate the potential consequences of a hazard. Consider the impact on people, property, and the environment.

- Use a scale of 1 to 5, where 1 represents low severity (minor injuries) and 5 represents high severity (fatalities).

- For example:

- 1: Minor injuries

- 3: Moderate injuries

- 5: Fatalities

- Likelihood Assessment:

- Determine the likelihood of the hazard causing harm. Consider factors like exposure frequency, control measures, and historical data.

- Again, use a scale of 1 to 5, where 1 represents low likelihood and 5 represents high likelihood.

- For example:

- 1: Rare occurrence

- 3: Occasional occurrence

- 5: Frequent occurrence

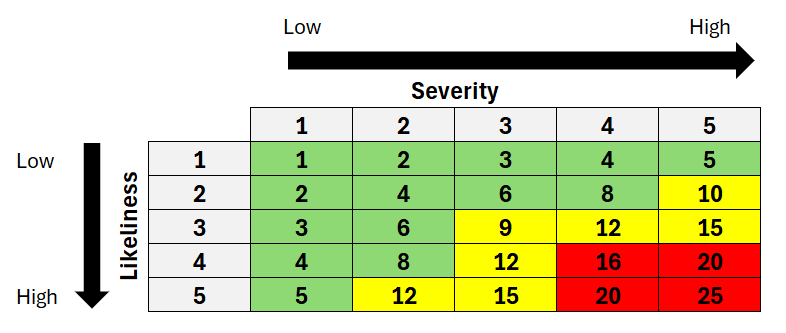

- Risk Matrix:

- Combine severity and likelihood to create a risk matrix. This matrix helps prioritize risks.

For example, if severity is 4 (high) and likelihood is 3 (moderate), the risk rating falls in the “High” category.

Risk Rating:

- Low: Low severity and low likelihood

- Medium: Moderate severity or moderate likelihood

- High: High severity or high likelihood

4. Precautions and Controls:

- Address risks according to their rating:

- High-risk hazards require immediate attention.

- Medium-risk hazards need action but with less urgency.

- Low-risk hazards still need monitoring and control.

5. Record your findings using a risk assessment template. Include details about hazards, severity, likelihood, and control measures.

6. Review your finding regularly to ensure you have the correct controls in place

3. Control Hazards:

- Implement effective measures to control risks. This could involve engineering controls (e.g., guarding machinery), administrative controls (e.g., training, signage), and personal protective equipment (PPE). Follow HSE guidelines on precautions specific to each hazard.

Think. What is the most effective way to control hazards?

- Elimination: Physically removing the hazard is the most effective control. For instance, if employees work at heights, eliminating the need for elevated work by moving tasks to ground level reduces the risk.

- Substitution: Replacing hazardous materials or processes with safer alternatives. While less prioritized than elimination, substitution aims to minimize risks associated with the substitute itself.

- Engineering Controls: These rely on system design and technology. Examples include installing ventilation systems, using machine guards, or designing ergonomic workstations.

- Administrative Controls: These depend on human behavior and procedures. They include training, signage, and restricted access to hazardous areas.

- Personal Protective Equipment (PPE): The last line of defence. PPE includes gear like gloves, goggles, and respirators. However, it relies on consistent compliance by individuals.

4. Record Your Assessment:

- Document your findings comprehensively, including the hazards identified, risk levels, and control measures. Keep records accessible and up-to-date.

- Review and Update:

- Regularly review and update your risk assessment. Adapt it when circumstances change (new equipment, processes, or personnel) and ensure compliance with legal requirements.

To help you out see an example template for a risk assessment here.

For Risk assessment help contact TP Safety or click here to learn about our services.

Explore our comprehensive offering of in-person or online courses and see how our expert-led sessions can help you achieve your professional goals.